What is a Backflow

Prevention Device

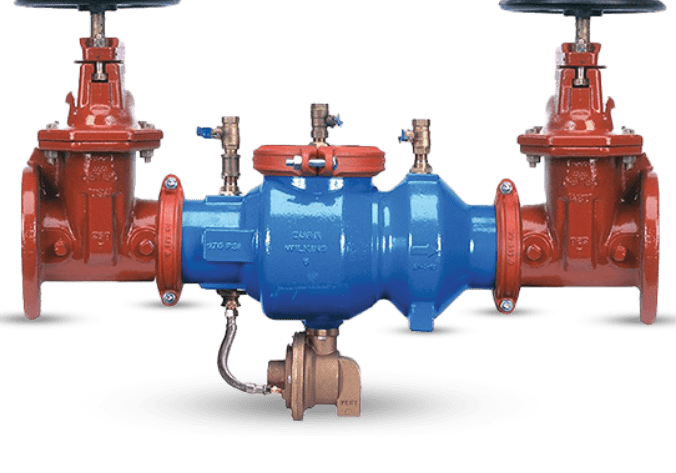

A backflow device, also known as a backflow prevention device, is a mechanism used to protect potable water supplies from contamination or pollution due to backflow. In water supply systems, water is usually maintained at a significant pressure to allow it to flow from the tap, shower, or other fixture.

Water pressure may fail or be reduced when a water main bursts, pipes freeze, or there is unexpectedly high demand on the water system. Reduced pressure in the pipe could allow contaminated water from the ground, from storage, or from other sources to be drawn into the system.

Backflow prevention devices are designed to block this backward flow into the water supply. They are essential in commercial, industrial, and high residential risk conditions where there’s a chance that a harmful substance might enter the water supply.